<>

“`

In recent years, 3D printing technologies have broken new ground as they evolve from prototyping simple objects to potentially revolutionizing large scale construction. When it comes to questions about the feasibility of 3D printing houses, there are multiple factors to consider including the technology behind it, the cost and time efficiency compared to traditional methods, and real-world examples that demonstrate its practicality. This blog post covers everything you need to know, from the underlying mechanics of 3D printing a house, to when these homes may be widely available, and includes a showcase of pioneering 3D-printed houses across the globe.

What Are 3D-Printed Houses?

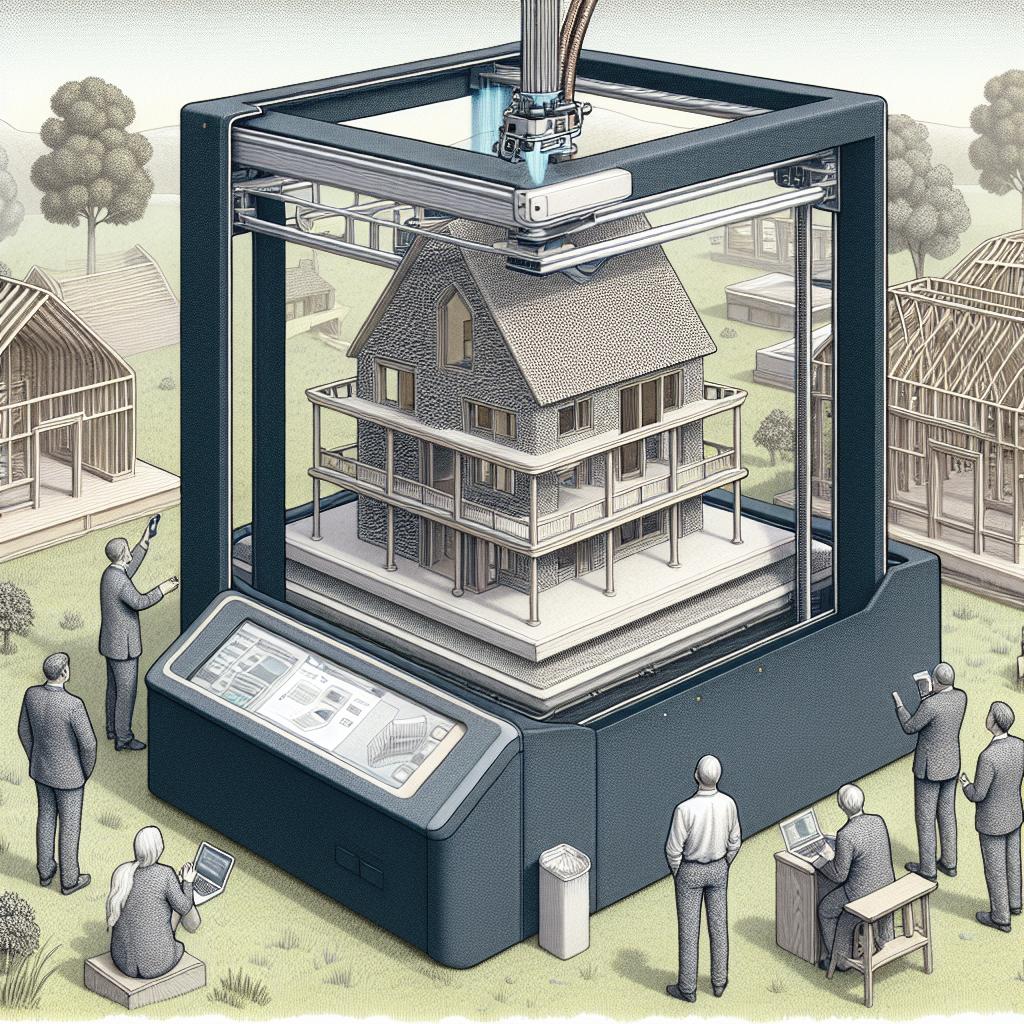

A 3D-printed house is a dwelling that is, in large part, constructed using a 3D printer. More specifically, the building components such as walls and supporting structures are created by extruding material—usually a type of concrete or other composites—layer by layer. This technology mimics the additive manufacturing process but on a much larger and more complex scale.

The appeal of 3D-printed houses lies in their potential to reduce construction time and labor costs significantly. These houses can also be customized more easily compared to traditional construction methods, potentially paving the way for a new era in home design and affordability. As the technology advances, the possibilities for what can be created with a 3D printer are expanding rapidly.

How Are 3D-Printed Houses Built?

The construction process begins with a detailed digital 3D model of the house, which is designed using specialized software. The 3D printer then reads this digital blueprint to erect structures layer by layer. The printer is usually a large robotic instrument capable of handling materials like concrete, which it “prints” by extruding through a nozzle continuously.

Once the foundational elements are constructed, additional elements such as windows, roofs, and interiors are completed using traditional building methods. However, research and development are ongoing to create printers that can manage a wider range of construction tasks, including creating complex roof structures and installing utility systems.

How Long Does It Take To 3D Print a House?

The time required to 3D print a house depends on the size and complexity of the structure, but it is generally much faster than traditional construction. In some cases, basic houses have been 3D printed in less than 24 hours. More complex buildings may take several days to a few weeks to complete.

This accelerated construction timeline results from the automation of the printing process, which allows for continuous, round-the-clock work without the need for breaks. However, it’s important to note that additional time may be required for finishing work and integrating traditional construction elements such as plumbing, electrical systems, and interiors.

How Much Does a 3D-Printed House Cost?

Costs for 3D-printed houses can vary widely depending on factors such as location, materials, and the complexity of the design. On average, a basic 3D-printed home can cost between $10,000 to $40,000. More elaborate designs can go up to $100,000 or more, though they often remain cheaper than traditionally built homes of similar size and quality.

Labor costs are significantly reduced because the 3D printing process is highly automated. Additionally, material waste is minimized, which is cost-efficient and environmentally friendly. This makes 3D-printed houses a particularly attractive option in regions with high construction costs or those facing housing shortages.

When Will 3D-Printed Houses Become Available?

Many companies and researchers are pushing the boundaries of what 3D printing can achieve in construction, with full-scale, 3D-printed homes already in existence. However, widespread adoption will depend on regulatory approval, technological advancements, and public acceptance. Current projections suggest that it may be a few years before 3D-printed houses become widely available on the market.

Safety regulations, building codes, and industry standards will need to adapt to accommodate this new technology. Early adopters are paving the way, and as successful case studies accumulate, it’s likely that 3D-printed homes will become more common. Partnerships between tech companies and construction firms will be crucial in driving this innovation forward.

Examples of 3D-Printed Houses

1. BioHome3D

BioHome3D is a notable example where sustainability is at the forefront. The house is made from bio-based materials, demonstrating a commitment to environmentally friendly construction. This innovation, spearheaded by the University of Maine and other stakeholders, aims to produce housing that’s both cost-effective and highly sustainable.

2. Citizen Robotics’ 3D-Printed Home

Located in Detroit, Citizen Robotics’ home exemplifies inner-city revitalization through innovative tech. Developed as an affordable housing solution, it showcases how 3D printing can rejuvenate urban areas plagued by housing shortages and high costs.

3. East 17th Street Residences

An entire residential community of 3D-printed homes, East 17th Street Residences in Austin, Texas, is perhaps one of the most ambitious projects. Developed by ICON and 3Strands, these homes were designed to be both affordable and stylish, addressing the housing crisis in one of America’s fastest-growing cities.

4. House 1.0

House 1.0, developed by the Eindhoven University of Technology, is part of the Project Milestone initiative. This house combines traditional and modern building techniques, using 3D-printed concrete elements alongside traditional construction methods to create a hybrid structure.

5. House Zero

An impressive blend of high design and sustainability, House Zero in Austin shows the potential of 3D printing in luxury markets. Developed by ICON, this home features customizable elements, making it a standout example of how 3D printing can cater to various market segments.

6. Kamp C

In Belgium, Kamp C is Europe’s first two-story 3D-printed house, achieving this feat in just three weeks. The project showcases the potential for rapid, multi-story construction using 3D printing technologies, setting a new benchmark in Europe.

7. Mense-Korte

The Mense-Korte house in Beckum, Germany, is a testament to the efficiency and practicality of 3D-printed construction. Utilizing advanced robotic systems, this house was built to meet strict German building codes, proving the viability of 3D printing in stringent regulatory environments.

8. Mighty House Quatro

As a product of the University of Nantes and the IAM architecture firm, Mighty House Quatro demonstrates the versatility of 3D printing through its innovative design. The house features complex shapes and organic forms, highlighting the design freedom 3D printing offers.

9. Project Milestone

Project Milestone, Eindhoven, Netherlands, aims to create five futuristic homes with intricate designs that are difficult to build using traditional methods. The initiative aspires to illustrate the prowess of 3D printing in overcoming conventional architectural limitations.

10. Tecla

Tecla, designed by Mario Cucinella Architects and created by WASP, is an Italian project focused on sustainability. Built using local, recyclable materials, Tecla is an eco-friendly house that’s completely off-grid, emphasizing the sustainable potential of 3D-printed homes.

Frequently Asked Questions

How much does a 3D-printed house cost?

The cost typically ranges from $10,000 to $40,000 for a basic structure, depending on factors such as size and materials. More elaborate designs can cost up to $100,000 or more.

How long does it take to 3D print a house?

Basic houses can be printed in as little as 24 hours, while more complex structures may take several days to a few weeks. Additional time for finishing and other construction tasks may also be required.

Where can I buy a 3D-printed house?

Currently, 3D-printed houses are primarily available through specialized companies and pilot projects. Widespread commercial availability is likely a few years away.

What is the downside of a 3D-printed house?

Challenges include regulatory hurdles, the current limitation of materials, and the need for specialized machines and expertise. Additionally, fully integrating traditional building elements with 3D-printed structures remains a challenge.

Lessons Learned

| Section | Summary |

|---|---|

| What Are 3D-Printed Houses? | 3D-printed houses are constructed using additive manufacturing techniques, layering materials like concrete to create walls and structures. |

| How Are 3D-Printed Houses Built? | The process starts with a digital 3D model, followed by layer-by-layer construction using a specialized 3D printer. |

| How Long Does It Take To 3D Print a House? | It can take anywhere from 24 hours to a few weeks, depending on the complexity of the structure. |

| How Much Does a 3D-Printed House Cost? | Costs vary from $10,000 to $100,000+, often less expensive than traditionally built homes of similar size and quality. |

| When Will 3D-Printed Houses Become Available? | Availability is currently limited, expected to become more widespread within a few years as regulations and technology catch up. |

| Examples of 3D-Printed Houses | Numerous examples exist globally showcasing different designs, materials, and purposes for 3D-printed homes. |

| Frequently Asked Questions | Covers costs, construction time, purchasing options, and potential downsides of 3D-printed houses. |

“`