<>

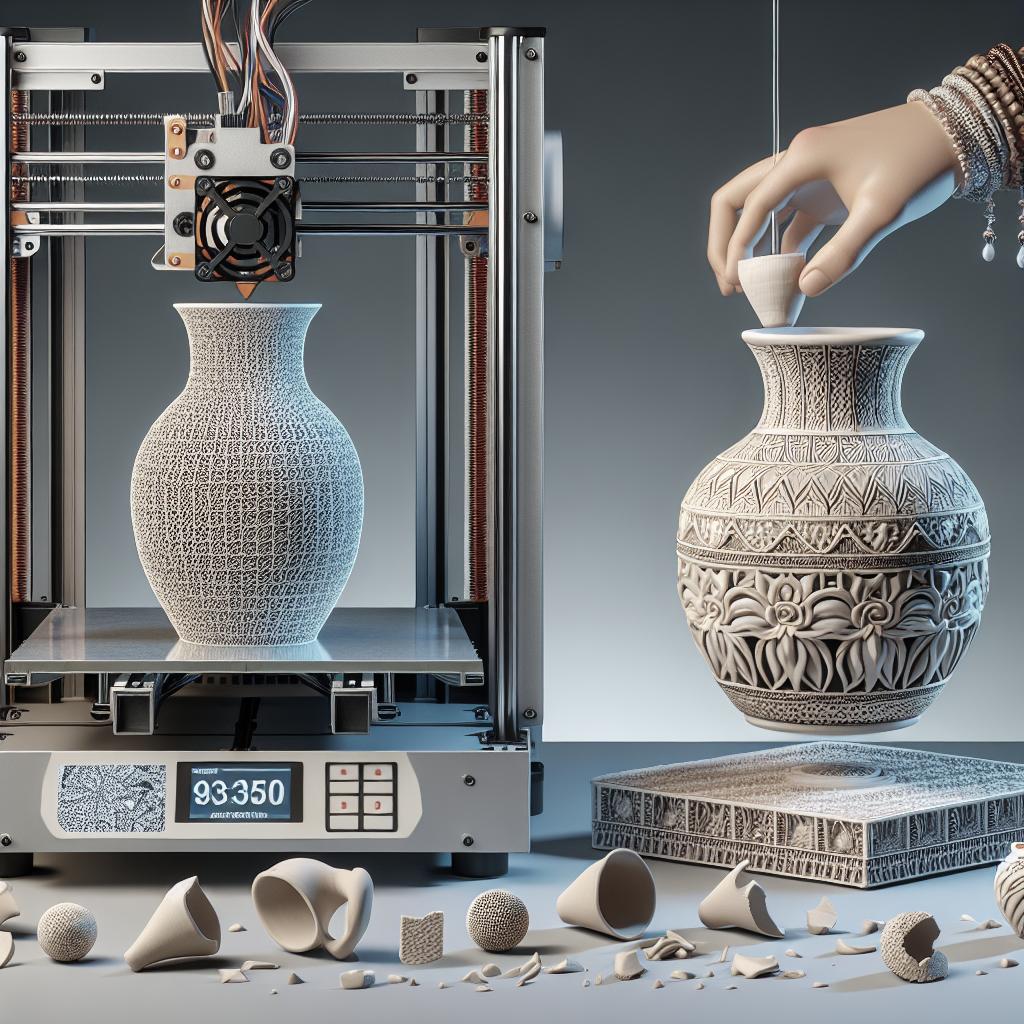

The realm of 3D printing has significantly expanded, with ceramic 3D printing emerging as a particularly groundbreaking area. Unlike traditional ceramics, 3D printed ceramics bring the precision, flexibility, and innovation of additive manufacturing to the world of material science. This blog post explores the durability of 3D printed ceramics, delving into the processes behind them, their applications in various industries, and the types of ceramics suitable for 3D printing. We’ll also take a closer look at the specialized field of ultra-high temperature ceramics composites. By understanding these aspects, we can appreciate the robustness and future potential of 3D printed ceramics in diverse fields.

3D Printing Ceramics

The journey of 3D printing ceramics starts with understanding the basic principles of additive manufacturing applied to ceramic materials. Unlike plastic or metal 3D printing, ceramic 3D printing involves materials that are brittle in nature but highly resistant to heat and wear. The process typically involves layer-by-layer deposition of ceramic materials, followed by sintering or firing to achieve the desired strength and durability. One of the main advantages of 3D printing ceramics is the ability to create intricate and complex geometries that are difficult, if not impossible, to achieve with traditional ceramic manufacturing methods. By using digital blueprints, manufacturers can precisely control the internal and external structures, optimizing them for specific uses. This precision not only enhances the performance characteristics but also minimizes waste, making the process more sustainable. Moreover, technological advancements have paved the way for new types of ceramic materials that can be used in 3D printing. From alumina and zirconia to silicon carbide, each material offers unique properties like high thermal resistance, electrical insulation, and mechanical strength. These attributes open up a myriad of applications, driving innovation across various industries.

Industries

One of the foremost industries benefiting from 3D printed ceramics is healthcare, particularly in the production of dental implants and bone scaffolds. Ceramic materials, such as zirconia, possess biocompatibility and strength that make them ideal for medical applications. With the capability to customize prosthetics to the exact specifications of individual patients, 3D printing significantly improves patient outcomes and simplifies the manufacturing process. The aerospace industry also leverages the advantages of 3D printed ceramics. Components made from ceramic materials endure high temperatures and resist corrosion, making them perfect for certain aerospace applications. For example, engine components that operate in extreme conditions benefit from the high thermal tolerance of ceramics. The process allows for rapid prototyping and reduced production time, aiding in the development of next-generation aerospace technologies. In the field of electronics, ceramic 3D printing is used to produce insulators, substrates, and other components that require precise geometries and high-performance characteristics. The ability to fabricate complex internal structures enhances the functionality of electronic devices. With the miniaturization of electronics becoming increasingly important, 3D printed ceramics present a viable solution to meet these modern challenges.

Types of Ceramic 3D Printing

The choice of the printing method can significantly affect the properties and applications of 3D printed ceramics. One popular method is Binder Jetting, where a liquid binding agent is selectively deposited to join powder particles layer by layer. The object is then subjected to a post-processing stage involving sintering to achieve the final, durable ceramic part. Binder Jetting is known for its ability to produce large, complex shapes with relatively good accuracy. Another significant method is Stereolithography (SLA)-based 3D printing. This technique utilizes a laser to solidify a photosensitive resin combined with ceramic particles. The process results in high-resolution, detailed ceramic parts, albeit with a relatively smaller build size compared to Binder Jetting. This method is preferable for applications requiring intricate details and a smooth surface finish. Laminated Object Manufacturing (LOM) is yet another approach, where thin ceramic sheets are cut and bonded layer by layer. While this method might not achieve the same level of complexity as Binder Jetting or SLA, it offers a cost-effective way to produce large ceramic parts. Each of these methods has its own pros and cons, making them suitable for different types of applications and material requirements.

3D Printing of Ultra-high Temperature Ceramics Composites

Ultra-high temperature ceramics (UHTCs) represent a specialized niche within the ceramic 3D printing landscape. Comprising materials like hafnium carbide and zirconium carbide, UHTCs can withstand temperatures exceeding 3000°C, making them ideal for severe environments such as hypersonic flight or nuclear reactors. These composites are often used to produce components that must endure extreme thermal gradients and mechanical stresses. The 3D printing of UHTCs involves meticulous control over the printing parameters to ensure uniformity and performance. Techniques such as Selective Laser Melting (SLM) and Direct Ink Writing (DIW) have proven effective in producing high-quality UHTC composites. The ability to tailor-make parts for specific aerodynamic properties or thermal resistance offers significant advantages in demanding applications. Research and development in the field of UHTCs are continually pushing the boundaries of what is possible. Innovations like hybrid materials and new printing methodologies promise to enhance the durability and functional characteristics of UHTC components further. As technological advancements continue, the applications of these high-performance ceramics will likely expand, underscoring their importance in cutting-edge industries.

| Aspect | Details |

|---|---|

| Basic Principles | Layer-by-layer deposition, sintering/firing, high heat and wear resistance. |

| Advantages | Complex geometries, precision, sustainability, new ceramic materials. |

| Industries | Healthcare (dental implants, bone scaffolds), Aerospace (high-temperature components), Electronics (insulators, substrates). |

| Types of Ceramic 3D Printing | Binder Jetting, SLA-based printing, Laminated Object Manufacturing (LOM). |

| UHTCs | Ultra-high temperature capabilities, techniques like SLM and DIW, future R&D prospects. |

By understanding these key aspects, we can appreciate the ongoing evolution of 3D printed ceramics as they become indispensable in multiple fields, presenting thrilling possibilities for future applications.