< lang="en">

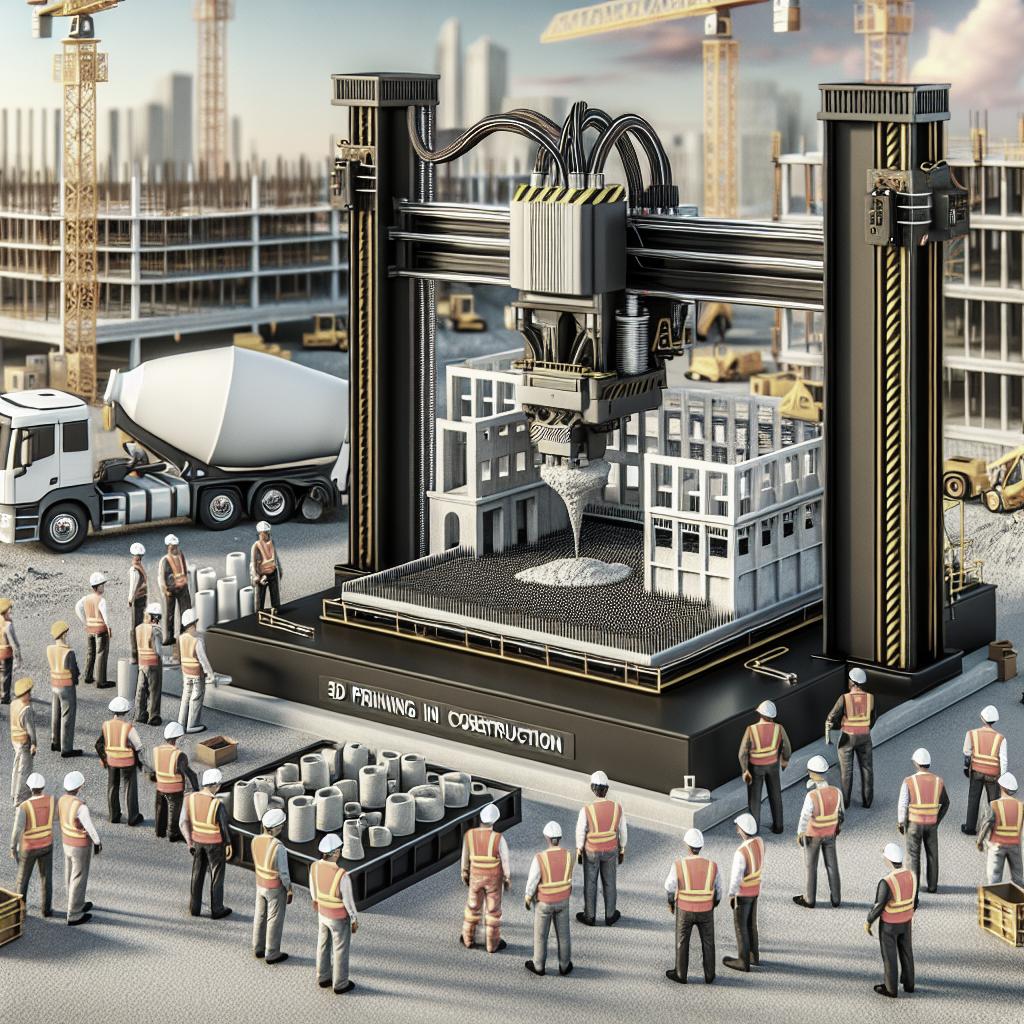

3D printing has made significant strides in various industries over the past decade, and construction is no exception. This groundbreaking technology is revolutionizing the way buildings and infrastructure are designed and built, offering numerous benefits including speed, cost savings, and sustainability. In this blog post, we will delve into what 3D printing in construction entails, how it’s executed, the benefits it brings, the opportunities and challenges it faces, and the types of 3D printers used in the industry. Additionally, we’ll answer some frequently asked questions about 3D printing in this sector.

What Is 3D Printing In Construction?

3D printing in construction, also known as additive manufacturing, involves the use of 3D printers to create building components directly from digital models. This technology allows for the additive creation of structures layer by layer, typically using materials such as concrete, plastic, or metal. The process starts with a digital blueprint, often derived from CAD (Computer Aided Design) software, which precisely guides the printer’s movements.

This method contrasts sharply with traditional construction techniques, which are often labor-intensive and time-consuming. By utilizing 3D printing, architects and builders can produce complex designs that would be difficult or impossible to achieve using conventional methods. Additionally, 3D printing can significantly reduce waste and streamline construction workflows.

How is 3D Printing Executed in Construction?

Executing 3D printing in construction involves several steps, beginning with the creation of a digital model. This model is then sliced into hundreds or thousands of layers by specialized software. The printer reads these layers and starts the printing process, which can often take several hours to days depending on the complexity and size of the project.

Materials such as specialized concrete mixtures or thermoplastic composites are extruded through a nozzle layer by layer, guided by the digital model’s specifications. The process is highly automated and requires precise calibration and monitoring to ensure the structure is sound and adheres to safety standards.

Benefits Of 3D Printing in Construction Industry

Speed and efficiency:

One of the primary advantages of 3D printing in construction is its speed. Traditional construction projects can take months or even years to complete, whereas a 3D printed building or component can be produced in a fraction of the time. This acceleration is due to the continuous, automated nature of 3D printing, which reduces the need for manual labor.

Cost savings:

3D printing can also significantly reduce costs. By minimizing material waste and labor expenses, construction firms can see substantial savings. The precision of 3D printing ensures that only the necessary amount of material is used, which also contributes to cost efficiency.

Design flexibility and customisation:

Traditional construction methods often limit architects in terms of design. With 3D printing, complex geometric shapes and intricate details can be easily produced, providing unmatched design flexibility. Customization is straightforward, allowing for highly tailored projects that meet specific client needs without incurring significant additional costs.

Sustainability:

The construction industry is notorious for its environmental impact, but 3D printing offers a more sustainable approach. It generates less waste than conventional methods and can utilize recycled materials, contributing to a reduction in the carbon footprint. Additionally, the enhanced efficiency of 3D printing reduces energy consumption.

Enhanced safety:

3D printing can improve safety on construction sites by reducing the need for workers to perform dangerous tasks. Automated machines carry out the bulk of the work, which minimizes human exposure to hazardous environments, thereby reducing the likelihood of accidents.

Remote construction:

One of the more interesting applications of 3D printing in construction is the ability to build in remote or harsh environments where traditional construction would be challenging. For example, this technology is being explored for use in building habitats on Mars or the Moon, as it can function autonomously and with limited human intervention.

Structural strength and durability:

Contrary to what some might think, structures built using 3D printing can be incredibly strong and durable. Advanced materials and precision engineering ensure that these buildings meet or exceed traditional construction standards, making them a viable option for various types of projects.

Opportunities And Challenges For 3D Printing in Construction

Opportunities:

3D printing in construction presents numerous opportunities for innovation and growth. It opens the door for new architectural designs, faster project timelines, and more cost-effective building methods. Moreover, it provides the means to address housing shortages globally by rapidly producing affordable homes.

Additionally, the use of local and recycled materials can bolster sustainability initiatives. The ability to build in remote or disaster-stricken areas further expands the potential applications of this technology.

Challenges:

Despite its promise, 3D printing in construction faces several challenges. One of the primary hurdles is regulatory approval. Building codes and regulations in many regions are not yet adapted to account for 3D printed structures, which can delay project timelines and increase costs.

The initial investment in 3D printing technology can also be quite high. Construction firms need to evaluate the long-term benefits versus the upfront costs of purchasing and maintaining 3D printers. Additionally, the technology is still evolving, and ongoing research and development are necessary to resolve existing limitations, such as issues with scalability and material consistency.

Types Of 3D Printers

Concrete extrusion printers:

Concrete extrusion printers are among the most commonly used in the construction industry. These machines extrude concrete layer by layer to build walls and other structures. They are designed to handle the dense, viscous nature of concrete, ensuring sturdy and reliable builds.

Robotic arm printers:

Robotic arm printers offer flexibility and precision, making them ideal for more intricate projects. These printers use a robotic arm to extrude materials, allowing for complex shapes and detailed work. They are often used in conjunction with other types of 3D printers to complete a project.

Gantry systems:

Gantry systems are large-scale 3D printers that operate on a framework of rails or beams. This setup allows for the printing of larger components or entire structures. Gantry systems are particularly useful for commercial and industrial projects due to their ability to cover extensive build areas.

FAQs

How is 3D printing used in construction?

3D printing in construction is used to create building components and entire structures directly from digital models. The process involves extruding materials layer by layer under precise guidance, significantly reducing waste and speeding up construction timelines.

What is 3D construction?

3D construction, also known as additive manufacturing in the construction industry, refers to using 3D printing technology to build structures. It involves creating physical objects by layering materials based on a digital blueprint, offering numerous benefits over traditional construction methods.

How is 3D printing used in architecture?

In architecture, 3D printing can be used to create detailed models and prototypes, allowing for better visualization and iterative design. It can also produce custom architectural elements and even entire building components, providing greater design flexibility and innovation.

How does 3D printing help the environment in construction?

3D printing helps the environment by reducing waste associated with traditional construction methods. It allows for the use of recycled materials and reduces energy consumption. The precision of 3D printing also ensures minimal material wastage, contributing to sustainability.

What are the benefits of 3D-printed construction?

The benefits of 3D-printed construction include faster build times, cost savings, enhanced design flexibility, improved sustainability, increased safety, and the ability to construct in remote or challenging environments. These advantages are driving the adoption of 3D printing technology within the industry.

What is the future of 3D printing in construction?

The future of 3D printing in construction looks promising, with ongoing advancements in technology and materials. The adoption of 3D printing could revolutionize the industry, making construction faster, more cost-effective, and environmentally friendly. However, widespread acceptance will depend on overcoming current challenges and regulatory hurdles.

What are the risks of 3D printing in construction?

Risks associated with 3D printing in construction include initial high setup costs, regulatory challenges, and potential material limitations. Additionally, the technology is still evolving, and there is a need for standardized procedures and quality controls to ensure safety and reliability.

Is construction using 3D printing technology sustainable?

Yes, construction using 3D printing technology can be quite sustainable. It reduces waste, lowers energy consumption, and allows for the use of recycled materials. This environmentally friendly approach is one of the key advantages of adopting 3D printing in the construction industry.

| Aspect | Details |

|---|---|

| Definition | 3D printing in construction involves creating structures layer by layer from digital models using materials like concrete, plastic, or metal. |

| Execution | Process includes creating a digital model, slicing it into layers, and then printing with precise controls using specialized materials. |

| Benefits | Includes speed, cost savings, design flexibility, sustainability, enhanced safety, remote construction, and structural strength. |

| Opportunities | Offers new design possibilities, faster timelines, cost-effective methods, housing solutions, and construction in remote areas. |

| Challenges | Faces regulatory issues, high initial costs, and technological limitations that require ongoing R&D. |

| Types of Printers | Includes concrete extrusion printers, robotic arm printers, and gantry systems for various applications. |

| FAQs | Covers how 3D printing is used, its benefits and sustainability, future prospects, and associated risks. |