<>

“`

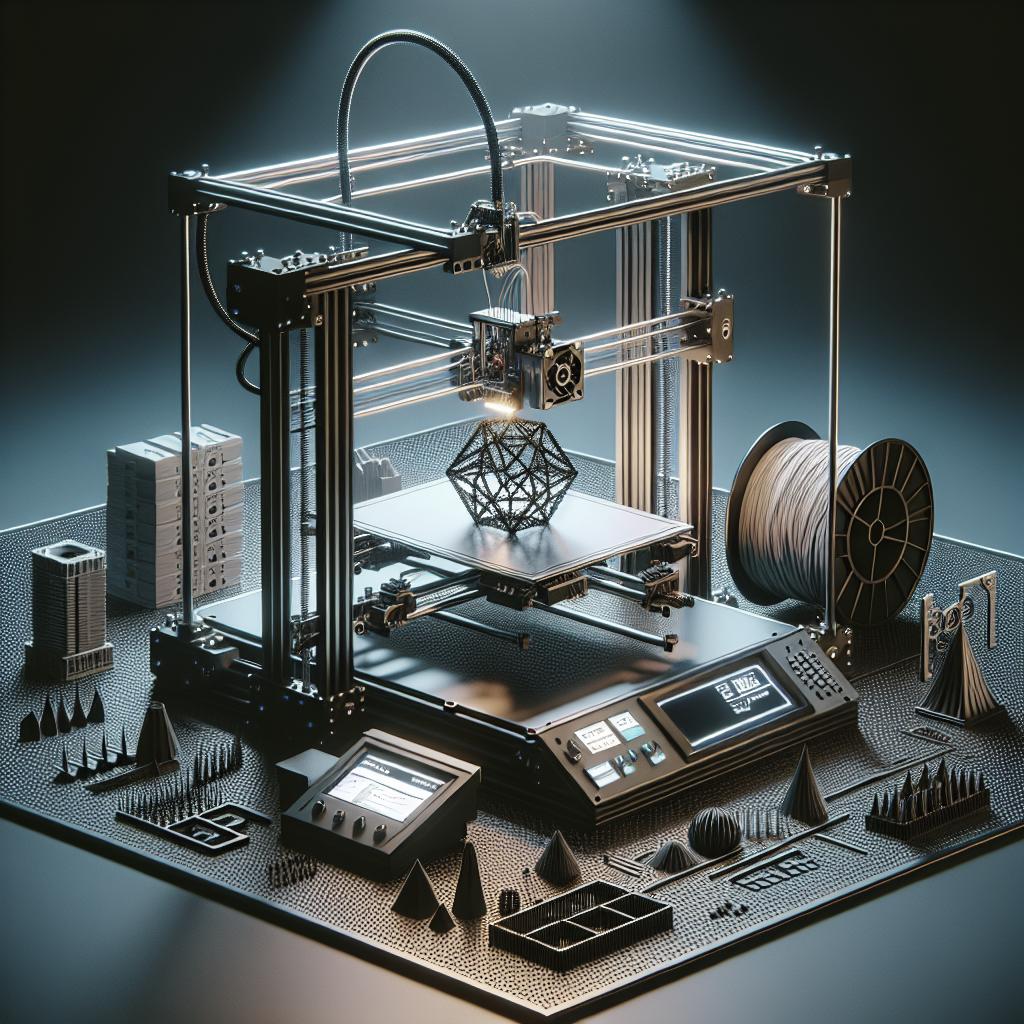

3D printing, often referred to as additive manufacturing, involves creating three-dimensional objects from digital files. This post explores the core components of 3D printing, including how it works, various technologies, materials used, industries impacted, and examples of applications. We’ll delve into the stages from 3D software to slicing, discuss different 3D printing processes like Vat Photopolymerization and Material Jetting, and showcase how 3D printing is revolutionizing sectors such as healthcare, automotive, and construction. By the end of this comprehensive overview, you’ll have a solid understanding of how 3D printing is reshaping innovation and production across multiple fields.

How Does 3D Printing Work?

The process of 3D printing starts with creating a digital 3D model using specialized software. This model serves as the blueprint for the object to be printed. The software is crucial as it shapes the design, dimensions, and overall structure of the desired object. Various 3D modeling programs, ranging from user-friendly apps to advanced software used by industry professionals, support different formats suitable for 3D printing.

3D Software

3D software, also known as Computer-Aided Design (CAD) software, is the first crucial step in the 3D printing process. Popular CAD software includes Autodesk Fusion 360, Blender, and Tinkercad. These programs allow users to design intricate and detailed three-dimensional models. Once designed, the model is often exported in file formats such as STL (stereolithography) or OBJ, which are compatible with most 3D printers.

Furthermore, some 3D software programs offer built-in tools to check and repair models, ensuring they are ready for printing. These tools can automatically fix issues such as gaps or irregularities in the design, which could potentially cause the print to fail. Mastery of 3D software is essential for anyone looking to fully leverage the potential of 3D printing technology.

Slicing: From file to 3D Printer

After creating a 3D model, the next step is slicing, which translates the digital model into instructions the 3D printer can understand. The slicing process involves dividing the model into thin layers. Each layer is then converted into a series of instructions called G-code, which guides the printer on how to create the object layer by layer.

Slicing software like Ultimaker Cura, PrusaSlicer, and Slic3r plays a critical role in this step. These programs not only slice the model but can also adjust settings such as layer height, print speed, and the use of support structures for more complex designs. Proper slicing ensures that the final printed object matches the integrity of the original digital model.

Types of 3D Printing Technologies and Processes

3D printing encompasses a variety of technologies and processes, each suited to specific applications and material types. These technologies vary from photopolymerization methods like stereolithography to material extrusion techniques like Fused Deposition Modeling. Understanding the distinct characteristics and capabilities of each helps in choosing the right method for the desired outcome.

Vat Photopolymerisation

Vat Photopolymerisation incorporates technologies like Stereolithography (SLA) and Digital Light Processing (DLP). In these processes, a liquid photopolymer resin is cured layer by layer using a light source such as a laser or a projector. SLA and DLP are renowned for producing high-resolution objects with intricate details, making them ideal for applications requiring precision.

The main difference between SLA and DLP lies in their light sources: SLA uses a laser to trace each layer, whereas DLP projects the entire layer at once. Despite the higher cost of photopolymer resins, the quality and detail achievable through Vat Photopolymerisation make it a popular choice for industries such as dentistry, jewelry, and engineering.

Material Jetting

Material jetting functions similarly to an inkjet printer, but instead of ink, it deposits droplets of photopolymer materials that solidify under UV light. This technology can print multiple materials and colors simultaneously, allowing for complex and highly customized objects. Companies like Stratasys have pioneered in developing material jetting printers that are highly versatile.

Material Jetting is widely used in producing prototypes and models where color and detail are crucial. The ability to print with various materials in a single print run makes it particularly useful for industries like automotive and consumer electronics, where aesthetic and functional prototypes are indispensable.

Binder Jetting

Binder Jetting involves depositing a liquid binding agent over a powder bed, layer by layer, to create an object. Once the object is formed, it often requires additional processing, such as sintering or infiltration, to achieve the desired mechanical properties. The technology is versatile, capable of using a wide range of materials, including metals, ceramics, and composites.

Binder Jetting is often deployed in making full-color models, metal parts, and tooling. Its ability to build parts without the need for support structures and with minimal material waste makes it a cost-effective option for various industrial applications.

Material Extrusion

Material Extrusion, commonly known as Fused Deposition Modeling (FDM), is the most popular and accessible form of 3D printing. It involves extruding thermoplastic filaments through a heated nozzle, which then deposits the material layer by layer to build an object. FDM printers are particularly favored for their affordability and ease of use.

This technology is widespread in both professional and hobbyist circles. While FDM can produce robust and functional parts, the surface finish and resolution might not match those of other technologies like SLA or SLS (Selective Laser Sintering). However, advancements in FDM, such as improvements in filament materials and printer capabilities, are continually enhancing its application scope.

Powder Bed Fusion

Powder Bed Fusion processes, including Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS), involve using a high-power laser to selectively sinter or melt powder particles layer by layer. This results in highly detailed and mechanically robust parts. Powder Bed Fusion is suitable for both plastic and metal materials.

SLS is often used for functional prototypes and end-use parts due to its ability to produce highly durable objects without the need for support structures. DMLS, on the other hand, is crucial in industries like aerospace and medical implants, where producing complex metal parts with excellent mechanical properties is essential.

Directed Energy Deposition

Directed Energy Deposition (DED) uses focused thermal energy to fuse materials as they are being deposited. This technology is predominantly used with metals, although it can also be employed with polymers and ceramics. The main advantage of DED is its ability to repair and add material to existing components.

DED often utilizes laser, electron beam, or plasma arc as the heat sources to melt the feedstock, which can be in powder or wire form. Industries such as aerospace, automotive, and defense use DED for repairing high-value parts and in-situ manufacturing, which involves creating or repairing parts directly on-site.

Materials

The types of materials available for 3D printing are as varied as the technologies themselves. Common materials include thermoplastics like PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) used in FDM, photopolymers for SLA and DLP, and metals like titanium and stainless steel for SLS and DMLS.

Advanced materials such as carbon fiber composites, ceramics, and bio-inks are also increasingly being utilized. These materials open new frontiers for 3D printing, from aerospace-grade components to complex biological tissues for medical research. The ongoing development in material science is continuously expanding the capabilities and applications of 3D printing.

3D Printing Industry

The 3D printing industry has seen exponential growth over the past decade, expanding into various sectors like healthcare, aerospace, automotive, and consumer goods. With advancements in technology, 3D printing is gradually shifting from a prototyping tool to a production technology.

Additionally, the entry of major tech companies into the market, alongside startups developing innovative solutions, has spurred increased competition and rapid technological advancements. The global 3D printing market continues to grow, making significant contributions to industrial digitization and smart manufacturing.

Examples of 3D Printing

Various industries are reaping the benefits of 3D printing, utilizing its capabilities to drive innovation, reduce costs, and improve efficiency. From rapid prototyping to custom manufacturing, 3D printing is enhancing production methods and enabling the creation of previously impossible designs.

Rapid Prototyping & Rapid Manufacturing

Rapid prototyping allows designers and engineers to quickly create, test, and iterate their designs. This significantly shortens the product development cycle and reduces costs. Rapid manufacturing, on the other hand, leverages 3D printing for small-scale production runs, allowing for greater customization and faster turnaround times.

Industries like consumer electronics, fashion, and industrial design use these processes to stay ahead of the competition and respond swiftly to market demands. The ability to rapidly prototype and manufacture offers a competitive edge in an increasingly fast-paced market.

Automotive

The automotive industry utilizes 3D printing to produce complex parts and prototypes. Companies like Ford and BMW use 3D printing for tooling, fixtures, and even end-use parts. This approach not only cuts down on lead times but also allows for more intricate and lightweight designs.

Furthermore, 3D printing enables the production of custom parts for vintage or limited-edition vehicles, providing a viable solution for producing components whose original manufacturing methods are no longer feasible or economical.

Aviation

In aviation, 3D printing is revolutionizing the manufacturing of complex parts and components. Companies like Boeing and Airbus are incorporating 3D printed parts that are lighter and more durable into their aircraft, thereby improving fuel efficiency and reducing costs.

The flexibility of 3D printing also allows for the creation of intricate geometries that are otherwise difficult or impossible to achieve with traditional manufacturing methods. This results in more efficient and optimized components that meet the stringent requirements of the aerospace industry.

Construction

3D printing in construction is an emerging field with the potential to revolutionize building methods. Large-scale 3D printers can print entire building structures using materials like concrete, significantly reducing labor costs and construction times.

Projects like 3D printed houses and bridges demonstrate the technology’s potential for creating affordable and sustainable housing solutions. The ability to produce complex architectural structures efficiently presents new opportunities for innovative designs and urban planning.

Consumer Products

From customized footwear to bespoke jewelry, 3D printing is transforming the consumer goods market. Companies are leveraging this technology to offer personalized products tailored to individual preferences, enhancing customer engagement and satisfaction.

The ability to produce complex and unique designs at a fraction of the cost of traditional manufacturing methods also opens new avenues for small businesses and entrepreneurs to enter the market with innovative products.

Healthcare

The healthcare industry benefits immensely from 3D printing, using it to create custom implants, prosthetics, and even bioprinted tissues and organs. This technology allows for precise customization to the patient’s anatomy, improving the effectiveness and outcomes of medical treatments.

Companies are pioneering the development of biocompatible materials and bioprinting techniques. Advancements in this area hold the promise of future medical breakthroughs, potentially leading to the development of fully functional organs for transplants.

Food

3D printing is making inroads into the food industry, with chefs and food tech companies using it to create intricate food designs and new culinary experiences. This technology can customize nutrition to individual dietary needs, potentially revolutionizing food production and consumption.

3D food printers can layer ingredients to create complex textures and flavors, offering innovative ways to present traditional dishes or develop entirely new recipes. This approach opens up exciting possibilities for personalized nutrition and sustainable food practices.

Education

Educational institutions are adopting 3D printing to enhance learning experiences in fields such as engineering, architecture, and medical studies. Students can turn their digital designs into physical objects, allowing for hands-on learning and a deeper understanding of complex concepts.

3D printing also enables the creation of affordable educational aids, such as anatomical models and engineering prototypes. This accessibility promotes creativity and innovation, preparing students for future careers in technology and manufacturing.

Services

Numerous services specialize in providing 3D printing solutions, offering expertise and resources for businesses and individuals. Companies like Shapeways, Sculpteo, and Materialise offer online platforms where users can upload designs and have them printed and shipped anywhere in the world.

These services cater to various needs, from prototyping and custom manufacturing to materials consultation and design support. Access to professional 3D printing services ensures that even those without their own 3D printers can benefit from this transformative technology.

| Section | Summary |

|---|---|

| How Does 3D Printing Work? | An overview of the process from 3D modeling software to slicing before printing. |

| Types of 3D Printing Technologies and Processes | Explanation of various 3D printing technologies like Vat Photopolymerisation, Material Jetting, and more. |

| Materials | Discussion on diverse materials used in 3D printing, from thermoplastics to metals and advanced composites. |

| 3D Printing Industry | Insights into the growth and evolution of the 3D printing industry across various sectors. |

| Examples of 3D Printing | Real-world applications of 3D printing in industries such as automotive, healthcare, construction, and more. |

| Services | Information on 3D printing services that offer accessible solutions for a range of projects. |

“`