<>

3D printing is revolutionizing industries by allowing rapid prototyping and the creation of complex structures. Among the crucial aspects of 3D printing is the resolution, which dictates the precision and quality of a printed object. Understanding and improving 3D printing resolution can be the difference between a detailed, functional model and a rough, inadequate one. In this blog post, we delve into what 3D printing resolution means, focusing on FDM (Fused Deposition Modeling) printers, explore the factors that affect resolution, and provide practical tips to enhance the resolution of your 3D prints. We’ll also examine some industry statistics and share insights from the latest advancements.

What is 3D Printing Resolution?

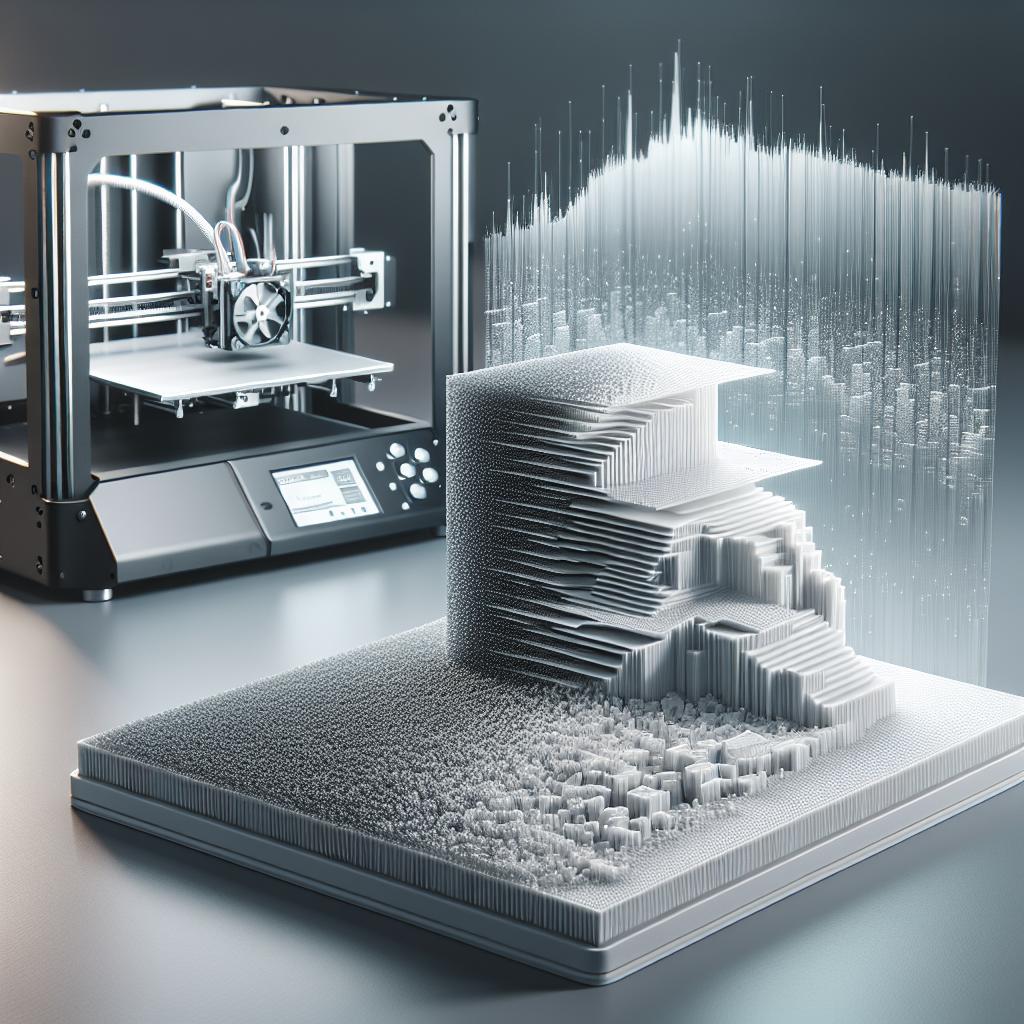

3D printing resolution refers to the level of detail, smoothness, and precision that a 3D printer can achieve when fabricating an object. It’s akin to the resolution in digital images, where higher resolution equates to more detail and clarity. In the realm of 3D printing, resolution is typically measured in microns (for layer height) or millimeters (for xy-axis precision). Both the layer height and the size of the extruder nozzle are instrumental in determining the finer details of a printed object. The layer height refers to the vertical resolution: a smaller layer height results in smoother surfaces and finer details but often takes more time to print. The nozzle size affects the horizontal resolution; a smaller nozzle can print finer details but may complicate the extrusion process and prolong print times.

Definition of FDM 3D Printer Resolution

FDM, or Fused Deposition Modeling, is one of the most common 3D printing technologies, particularly favored for its affordability and ease of use. In FDM 3D printing, the resolution can be defined by the smallest movement the printing head can make, combined with the layer thickness, which dictates vertical resolution. Typically, FDM printers offer layer heights ranging from 50 to 300 microns. The lower the micron count, the higher the resolution. However, lower layer heights also slow down the printing process because more layers are required to build the object. Additionally, FDM printers generally come with adjustable nozzle sizes, usually between 0.1mm and 1.0mm. The smaller the nozzle, the more detailed the print, but it may also increase the risk of clogging and can make the printing process more time-consuming. Accuracy is another critical factor to consider. Even if a printer has a high resolution, if it is not accurate, the printed object may not match the intended design. Therefore, to achieve high resolution in FDM printing, one must balance layer height, nozzle size, and positional accuracy.

How to Improve the FDM 3D Printer Resolution

Improving the resolution of your FDM 3D printer involves a multifaceted approach. Begin by selecting the appropriate nozzle size. Generally, a smaller nozzle size will enable finer details, but ensure that the filament choice complements the nozzle to prevent frequent clogs. Materials like PLA are usually beginner-friendly and perform well with fine nozzles. Adjusting the layer height is another crucial step. By setting a smaller layer height, the print will exhibit smoother surfaces and finer details. However, this adjustment will elongate the print time, so balancing quality and efficiency is essential. Experiment with different layer heights to find the optimal setting for your specific project. Proper calibration and maintenance of the printer further enhance resolution. Regularly check the bed leveling, extruder calibration, and belt tensions. Also, consider using software that enables micro-adjustments to improve accuracy. Upgrading your printer’s firmware or employing advanced slicing software can provide more control over print settings, contributing to better resolution.

2- 3D Printer Resolutions: Facts and Figures:

It’s essential to ground our understanding in concrete statistics. Recent data shows that FDM printers, on average, achieve resolutions between 50 and 300 microns in layer height and approximately 0.1mm to 1mm in xy-axis precision. However, some high-end FDM printers can reach up to 20 microns for layer height, rivaling more advanced technologies. According to a survey of industry professionals, about 70% consider resolution to be a critical factor influencing their purchase decisions for 3D printers. Higher resolutions are particularly crucial in industries like healthcare, aerospace, and jewelry, where intricate designs and precision are imperative. Another critical statistic from market analyses indicates that as printers with higher resolutions become more affordable, their adoption rate is increasing significantly. This trend underscores the growing importance of resolution in the broader 3D printing ecosystem.

2- What are the Factors Affecting Resolution in 3D Printers?

Several factors affect the resolution of 3D prints. The nozzle size, as mentioned earlier, plays a significant role. A smaller nozzle diameter offers higher resolution but requires more precise control over the extrusion process. Material choice also impacts resolution; different materials have varying melting points, viscosities, and flow characteristics, all of which influence the fineness of the print. Print speed is another crucial factor. Higher speeds can compromise the print resolution because the extruder may not place the layer accurately. Therefore, tuning the speed settings to complement your desired resolution and material is vital. Environmental conditions, such as temperature and humidity, can also affect the resolution. Variations in these conditions can lead to warping or layer shifting, decreasing print quality. Ensure a controlled environment for more consistent and higher-quality prints.

3- How to Improve the Resolution of My 3D Printer?

Start with proper calibration. A well-calibrated printer is the first step towards achieving high resolution. Calibrate the bed, nozzle, and other components regularly. This process minimizes errors and ensures that each layer is accurately placed. Experimenting with different filaments can also yield better results. Some filaments are designed for high-resolution printing and can significantly improve the quality of finer details. Additionally, consider upgrading to hardware with better resolution capabilities if your current setup is not delivering the desired results. Finally, leverage advanced slicing software that allows for fine-tuning of printing parameters. Programs like Cura, PrusaSlicer, and Simplify3D offer extensive customization options. Use these tools to adjust settings such as layer height, print speed, and extrusion width to achieve optimal resolution.

READ MORE: Guide to SLA 3D Printing and Its 10 Best Printing Services To wrap up, let’s look at a concise summary of what we’ve discussed: “`

| Aspect | Details |

|---|---|

| 3D Printing Resolution | Measures the detail and precision of a printed object, typically in microns or millimeters. |

| FDM Printer Resolution | Depends on layer height, nozzle size, and positional accuracy, usually between 50-300 microns. |

| Improving Resolution | Involves selecting appropriate nozzle size, adjusting layer height, and maintaining proper calibration. |

| Factors Affecting Resolution | Nozzle size, material choice, print speed, and environmental conditions. |

| Tips for Better Resolution | Proper calibration, experimenting with different filaments, and using advanced slicing software. |

“` By focusing on these key factors and employing best practices, you can significantly enhance the resolution of your 3D prints, producing more detailed and precise objects. As technology evolves, staying informed and continually refining your techniques will be essential in leveraging the full potential of 3D printing. Explore this further with our detailed guide on SLA 3D printing and its top services.