<>

When it comes to advanced manufacturing technology, SLA (stereolithography) stands out as one of the most detailed and precise 3D printing methods available today. Providing impressive accuracy and a great surface finish, SLA 3D printing has been widely adopted for prototyping and production in various industries, such as healthcare, dentistry, and engineering. This blog post aims to explore what SLA 3D printing is, how it operates, and its myriad applications. We’ll go through how to optimize print parameters, understand the unique characteristics of SLA, and delve into the materials and post-processing options available. We’ll also investigate the differences between desktop and industrial SLA 3D printers, highlight the advantages and disadvantages, and share some expert tips and tricks. By the end, you’ll have a comprehensive understanding of SLA 3D printing and its potential uses. —

What is SLA (stereolithography)?

SLA, or stereolithography, is one of the oldest and most reliable forms of 3D printing technology. Invented in the 1980s by Charles Hull, it uses a vat of liquid UV-curable photopolymer resin and a laser to build parts layer by layer. The laser selectively cures and hardens specific regions of the resin, which solidifies to form the 3D object. What sets SLA apart from other 3D printing techniques is its ability to produce highly detailed and accurate prints with smooth surface finishes. This precision makes it ideal for applications that require intricate details, such as in the dental industry for orthodontic models or in engineering for functional prototypes.

Watch before you read: How to get the most out of SLA printing

Before diving deeper into the technicalities of SLA 3D printing, it’s beneficial to watch a tutorial video that can provide visual insights into the process. Various online platforms, such as YouTube, offer comprehensive guides and tips to help you understand the nuances of SLA printing. These videos can be helpful in grasping the setup, calibration, and maintenance tasks that will ensure the best print quality and longevity of your equipment. Additionally, seeing the actual process can help you appreciate the precision and capabilities of SLA printing, making the upcoming sections easier to understand and relate to your projects.

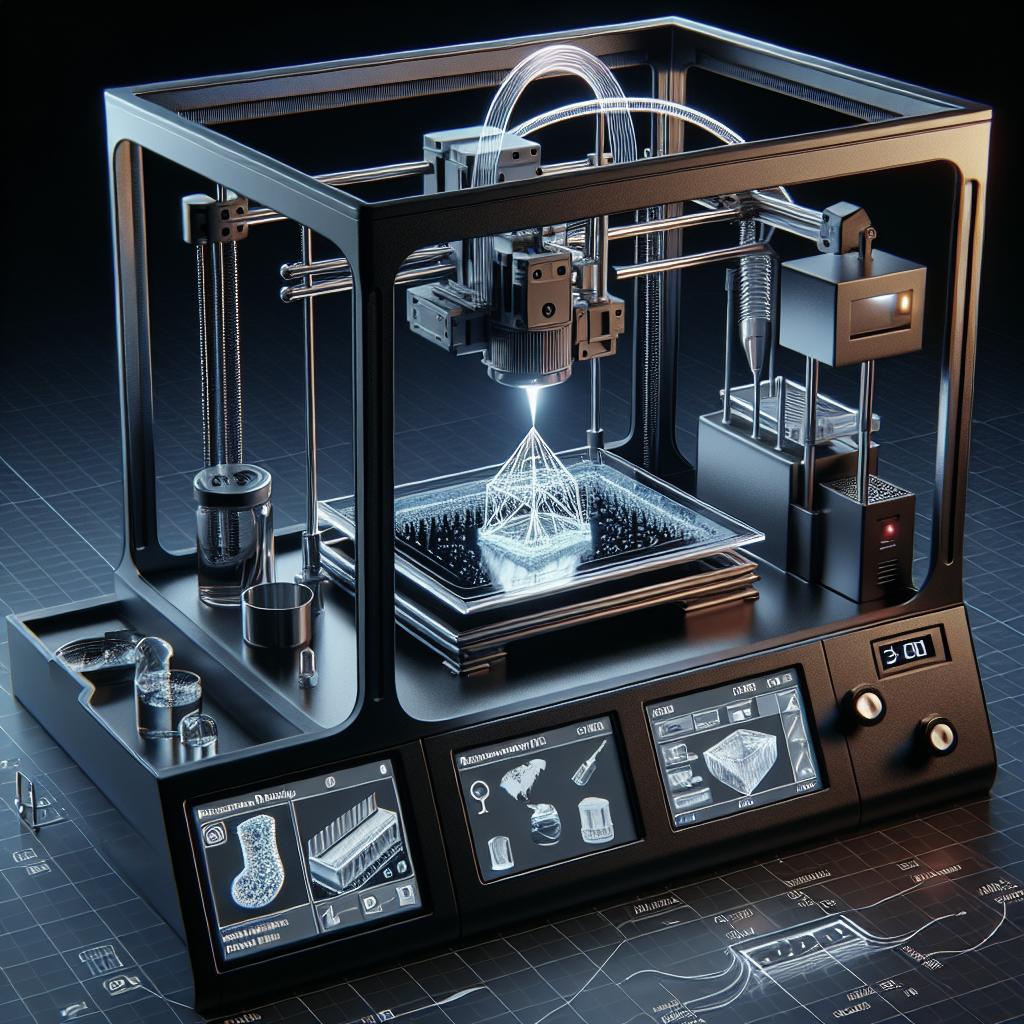

How does SLA 3D printing work?

SLA 3D printing begins with a digital 3D model created using CAD (Computer-Aided Design) software. This model is sliced into thin horizontal layers and loaded into the SLA printer. The printer contains a vat filled with liquid photopolymer resin, which is sensitive to UV light. A UV laser precisely targets the resin surface, curing and solidifying the material layer by layer. As each layer is completed, the build platform in the vat moves incrementally lower, allowing the next layer of resin to be cured on top of the previous one. This process continues until the entire object is printed. Several factors impact the success of an SLA print, including the resin type, laser strength, and layer thickness. Proper calibration and understanding of these parameters are crucial to achieving the desired print quality.

What are the print parameters of SLA?

Achieving optimal results in SLA 3D printing relies on a careful selection and tuning of print parameters. Critical among these are layer thickness, laser power, and exposure time. Layer thickness determines the vertical resolution of the print. Finer layers produce higher-detail prints but increase the printing time. Typical layer thicknesses range from 25 microns for high-detail prints to 100 microns for faster, less detailed printing. Laser power and exposure time are intertwined. Higher laser power or longer exposure times will cure the resin more thoroughly but can also lead to over-curing and potential distortion. Proper balance is necessary to ensure the right level of curing without compromising the integrity of the print.

What are the characteristics of SLA 3D printing?

SLA 3D printing has distinctive characteristics that set it apart from other forms of 3D printing. Understanding these can help optimize the printing process and improve the final product’s quality.

Support structures

One of the critical aspects of SLA printing is the necessity for support structures. These supports are integral to the printing process, providing stability to overhanging or complex geometries as the print layers are being built. Proper support placement is essential to prevent print failures and ensure a smooth finish on intricate details.

Curling

Curling is a common issue in SLA printing, where the edges of the print warp or lift. This can occur due to uneven exposure to the UV laser, rapid curing, or inadequate support structures. To mitigate curling, ensuring even curing and appropriate support placement is crucial. Some slicer software also provides settings to counteract and reduce curling.

Layer adhesion

Layer adhesion is paramount in achieving strong and durable prints. Proper exposure time and laser power settings ensure each layer is adequately bonded to the previous one, preventing delamination or weak points in the print.

Accuracy of SLA printing

One of the standout features of SLA 3D printing is its exceptional accuracy. The precision of the UV laser allows for extremely fine details, making it possible to create complex geometries with a high level of intricacy. Accuracy in SLA printing is influenced by factors such as the quality of the resin, the calibration of the laser, and the settings of the print parameters. When these are optimized, SLA prints can achieve tolerances as tight as 0.01 mm, suitable for applications requiring stringent dimensional accuracy, such as in medical device manufacturing.

Surface finish

SLA-printed parts are well-regarded for their smooth surface finish, which often requires minimal post-processing compared to other 3D printing technologies like FDM (Fused Deposition Modeling). The fine layer thickness and precise laser curing contribute to the sleek and polished appearance of SLA prints.

Summary of the main characteristics of SLA 3D printing

– Exceptional accuracy and fine details. – Smooth surface finish with minimal post-processing. – Need for support structures to stabilize intricate designs. – Issues such as curling and layer adhesion, which require careful optimization.

What materials are used for SLA printing?

SLA printing primarily uses photopolymer resins, which are liquid materials that harden when exposed to UV light. These resins can be engineered to exhibit a vast range of properties. Common resin types include standard resin for general purposes, tough resin for durable prints, flexible resin for elastic parts, and biocompatible resin for medical applications. Specialized resins are also available for specific industries. For example, dental resins are used for creating precise dental models and surgical guides, while castable resins are designed for creating patterns for investment casting.

What are the options for SLA post-processing?

Post-processing is often necessary to achieve the desired mechanical properties and aesthetic quality of SLA printed parts. Common post-processing steps include washing, curing, and finishing. After printing, parts are typically rinsed in isopropyl alcohol (IPA) to remove excess resin. This step is crucial for preventing any residue from affecting the final quality. The parts are then cured under UV light to ensure full polymerization of the resin, enhancing the material’s strength and stability. Finishing steps can involve sanding, painting, or coating to achieve the desired surface texture and appearance. Depending on the application, additional post-processing techniques like electroplating or applying a protective coating might also be used.

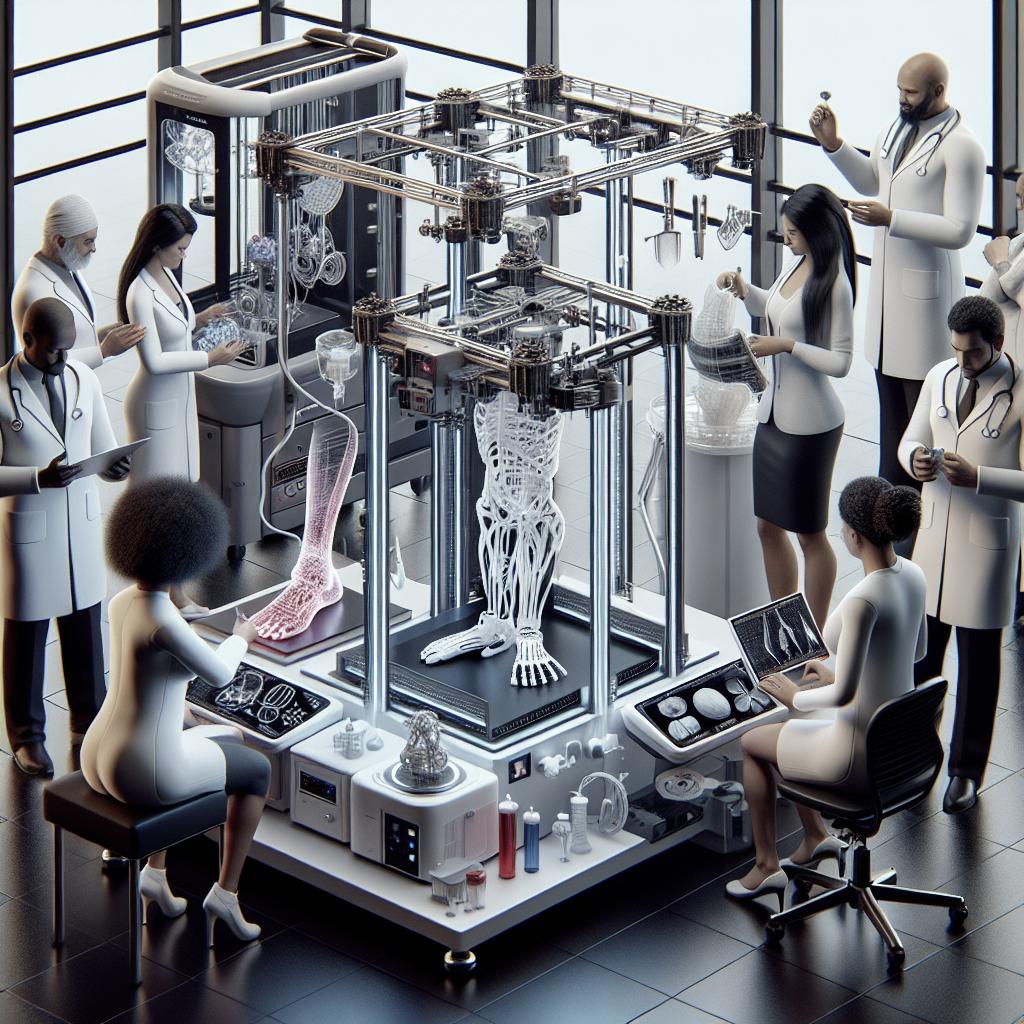

Applications of SLA 3D printing

SLA 3D printing is highly versatile, finding applications in numerous fields. In healthcare, it’s used to produce dental implants, prosthetics, and anatomical models. The high precision and smooth finish of SLA prints are perfect for creating patient-specific solutions. In the engineering and manufacturing sectors, SLA printing is employed for rapid prototyping and creating custom parts. The ability to produce highly detailed prototypes allows engineers to test and refine designs before moving to mass production. The jewelry industry also benefits from SLA 3D printing by creating detailed and intricate designs that would be challenging to craft manually. Castable resins can be used to print patterns for investment casting, streamlining the jewelry production process.

What’s the difference between desktop (prototyping) and industrial SLA 3D printers?

Desktop SLA printers are often used for prototyping and small-scale production. They are more affordable and compact, making them suitable for small businesses, hobbyists, and educational institutions. Although they offer high precision, their build volume and speed might be limited compared to industrial printers. Industrial SLA printers, on the other hand, are designed for large-scale manufacturing. They offer bigger build volumes, faster print times, and more robust construction. Industrial machines are capable of producing multiple parts in a single print run, making them ideal for mass production environments.

What are the advantages of SLA 3D printing?

SLA 3D printing offers several advantages that make it a standout technology. The precision and detail achievable with SLA are unparalleled, making it ideal for applications requiring high accuracy and intricate designs. The smooth surface finish of SLA prints also reduces the need for extensive post-processing, saving time and resources. Additionally, the wide range of available resins broadens the scope of applications, allowing for customized material properties tailored to specific needs.

What are the disadvantages of SLA 3D printing?

Despite its many advantages, SLA 3D printing does have some drawbacks. The need for support structures can complicate the printing process and require additional post-processing steps to remove them. Curling and layer adhesion issues can affect print quality, requiring careful optimization of print parameters. Additionally, the cost of resins and the specialized equipment can be higher compared to other 3D printing technologies, raising the overall investment required.

Top tips & tricks for SLA 3D printing

To get the most out of your SLA printing experience, consider the following tips: – Ensure your printer is well-calibrated and maintain it regularly. – Use the recommended resin for your specific application and store it properly to prevent degradation. – Optimize your print parameters based on the design and material properties, focusing on layer thickness, laser power, and exposure time. – Regularly clean and inspect the build platform and resin vat to prevent contamination and ensure consistent print quality. – Carefully plan the placement of support structures to minimize their impact on the final print while providing adequate stability.

Frequently asked questions

Q: How long does an SLA print take? A: The print time depends on the object’s size, complexity, and layer thickness. Smaller, less intricate parts can take a few hours, while larger, more detailed prints may require several days. Q: Can SLA prints be used for functional parts? A: Yes, SLA prints can be used for functional parts, especially when using tough or engineering resins designed for durability and mechanical properties. Q: What is the shelf life of SLA resin? A: The shelf life of SLA resin varies by manufacturer but is generally around 12 months when stored properly in a cool, dark place. Q: Is SLA printing environmentally friendly? A: SLA printing can generate waste, primarily from uncured resin and support structures. Some resins are not biodegradable, but recent developments in eco-friendly resins aim to address these concerns. Q: Do I need special software for SLA 3D printing? A: Most SLA printers come with proprietary slicing software designed to prepare 3D models for printing. Open-source slicing software is also available but might require additional configuration. —

Future prospects

| Aspect | Details |

|---|---|

| What is SLA | SLA is a detailed 3D printing method using UV-curable resin and a laser. |

| How it works | A laser selectively cures resin layer by layer to build the final object. |

| Print Parameters | Key parameters include layer thickness, laser power, and exposure time. |

| Characteristics | Support structures, curling, and layer adhesion are critical considerations. |

| Accuracy | SLA can achieve extremely fine details with tolerances around 0.01 mm. |

| Surface Finish | SLA-printed parts have smooth finishes, requiring minimal post-processing. |

| Materials | SLA uses photopolymer resins with various properties and applications. |

| Post-Processing | Common steps include washing, curing, and finishing. |

| Applications | Including healthcare, engineering, and jewelry. |

| Printer Types | Desktop for prototyping vs. industrial for large-scale manufacturing. |

| Advantages | High accuracy, smooth finishes, and diverse material options. |

| Disadvantages | Support structure requirements, curling issues, and cost. |

| Tips & Tricks | Regular calibration, proper resin storage, and optimal print parameter settings. |

Understanding SLA 3D printing’s intricacies allows for more informed use and opens up endless possibilities in design and manufacturing. While the technology has its challenges, continuous advances in materials and techniques promise a bright future for SLA in various sectors.