< lang="en">

3D printing, also known as additive manufacturing, has revolutionized the manufacturing industry. This technology involves creating three-dimensional objects from a digital file by layering materials. The versatility and efficiency of 3D printing make it a game-changer across various industries, including automotive, healthcare, and construction. In this blog post, we will delve into the intricacies of how 3D printing works, explore its applications across different sectors, examine the types of 3D printing technologies and materials used, and highlight some of the services available for leveraging this revolutionary technology. By the end, you will have a comprehensive understanding of the role of 3D printing in modern manufacturing.

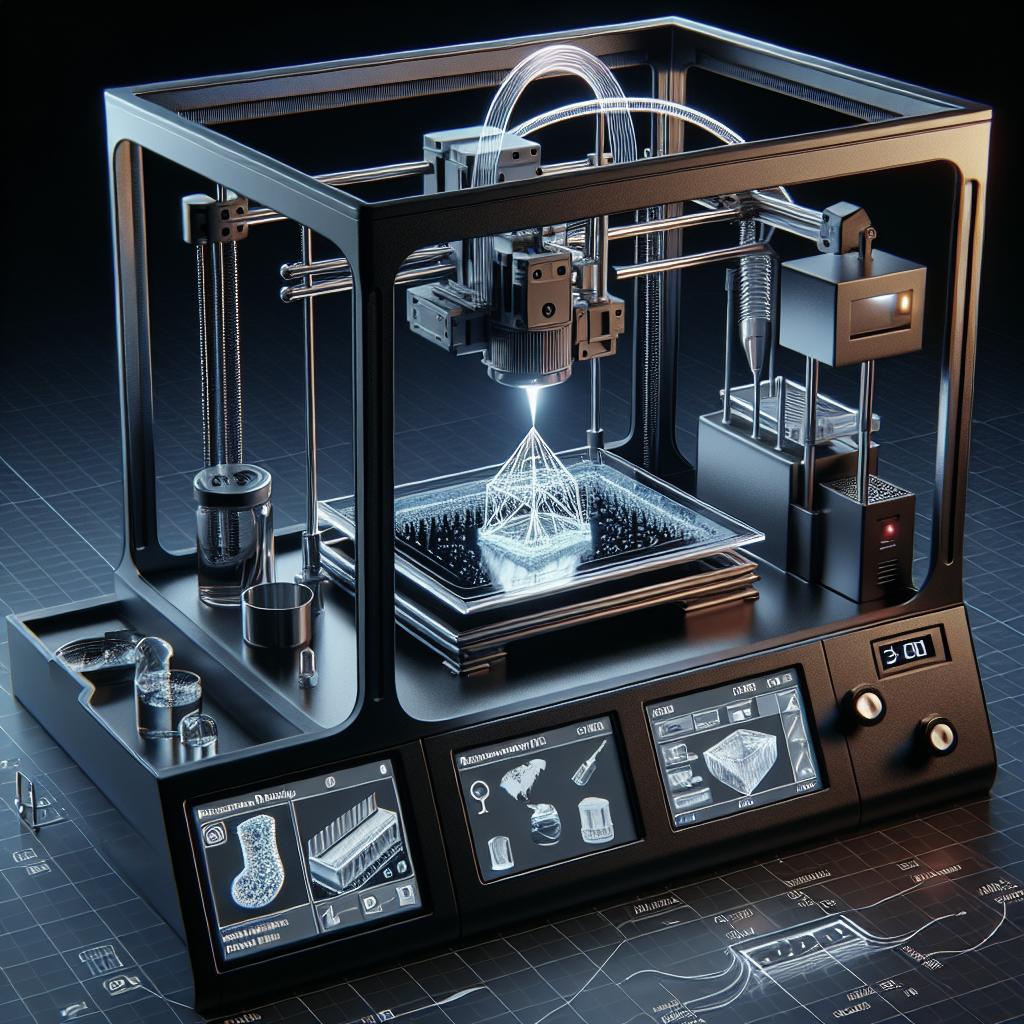

How Does 3D Printing Work?

3D Software

The journey of a 3D printed object begins with a digital blueprint created using Computer-Aided Design (CAD) software. This design process allows engineers and designers to visualize and refine the product before it goes into production. Popular 3D modeling software includes Autodesk, Blender, and SolidWorks, which provide robust tools to create intricate designs, simulate mechanical properties, and ensure that the model is ready for printing.

Once the 3D model is complete, it is exported in a standard file format such as STL (stereolithography) or OBJ (object file), which the 3D printer can interpret. This digital file contains all the necessary parameters for the 3D printer to execute the task flawlessly, such as dimensions, geometry, and layer information.

Slicing: From File to 3D Printer

Before the 3D printing process can commence, the digital model must be sliced into thin horizontal layers using slicing software. This software converts the 3D model into a series of 2D layers, generating G-code that directs the printer on how to create each layer. Tools such as Cura, Simplify3D, and PrusaSlicer are popular choices for this crucial step, offering features like support structure generation, infill pattern selection, and print optimization.

The slicing process also involves adjusting various parameters like layer height, print speed, and temperature settings to ensure the final product meets the desired specifications. Once the slicing is complete, the G-code is uploaded to the 3D printer, effectively bridging the gap between the virtual and physical worlds.

3D Printing Industry

The 3D printing industry has witnessed exponential growth over the past decade, making significant strides in industrial production. Initially focused on rapid prototyping, it has evolved into a mainstream manufacturing technique across various sectors. This shift has been driven by advancements in printer technology, material diversity, and the constant innovation within the industry.

According to a report by Wohlers Associates, the global 3D printing industry was valued at over $12 billion in 2020 and is expected to surpass $35 billion by 2025. This growth is attributed to the expanding applications of 3D printing, increased accessibility of advanced printers, and a growing ecosystem of service providers.

Examples of 3D Printing

Rapid Prototyping & Rapid Manufacturing

3D printing is a cornerstone technology for rapid prototyping, allowing companies to quickly iterate and refine product designs. Unlike traditional methods, which can be time-consuming and costly, 3D printing enables the rapid production of functional prototypes, thus accelerating product development cycles.

In addition to prototyping, 3D printing is increasingly used for rapid manufacturing of end-use parts. Low-volume production and custom part fabrication benefit from the flexibility and cost-efficiency offered by 3D printing, making it a viable option for many industries.

Automotive

The automotive sector has embraced 3D printing for prototyping, tooling, and even producing final components. Companies like Ford and BMW use 3D printing to streamline manufacturing processes and produce custom parts, reducing lead times and minimizing wastage.

Applications include designing intricate parts like engine components, custom interiors, and lightweight structures to improve vehicle performance and fuel efficiency.

Aviation

In aviation, the ability to produce lightweight and highly complex parts makes 3D printing an invaluable asset. Companies like Boeing and Airbus use 3D printing to manufacture parts such as fuel nozzles, door hinges, and even entire wing sections.

This capability not only enhances performance but also contributes to significant weight reduction, leading to lower fuel consumption and reduced emissions.

Construction

The construction industry has witnessed remarkable advancements with the introduction of 3D printing. Entire buildings and structures can now be printed, drastically reducing construction time and labor costs. Companies like Apis Cor and ICON are at the forefront of this revolution, constructing homes and commercial buildings using 3D printing technology.

Furthermore, 3D printing allows for the creation of intricate architectural designs that would be challenging and expensive using traditional construction methods.

Consumer Products

From customized jewelry to personalized phone cases, 3D printing offers endless possibilities in the realm of consumer products. Companies and individuals can produce one-of-a-kind items tailored to individual preferences, opening up new markets and opportunities for creativity.

The ability to produce complex geometries and intricate details makes 3D printing an ideal choice for creating unique and innovative consumer products.

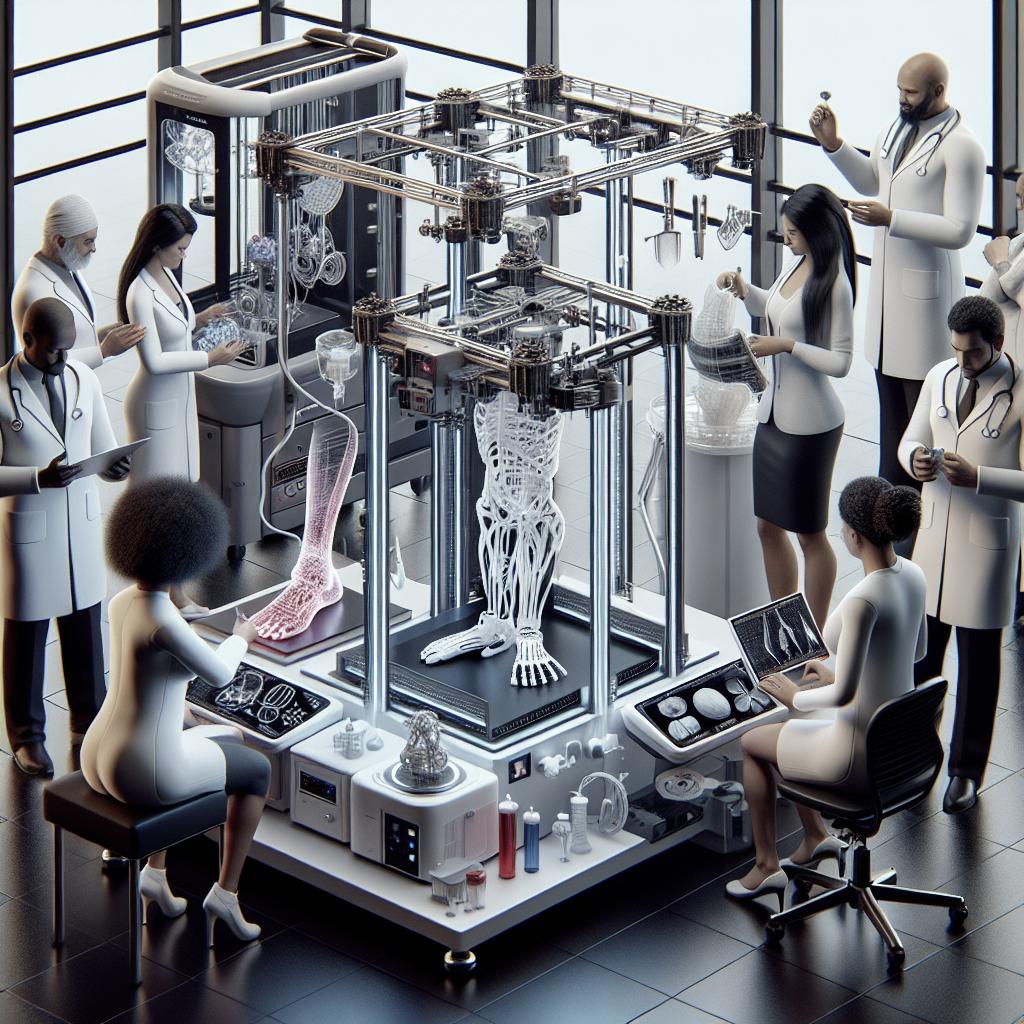

Healthcare

In healthcare, 3D printing has transformative potential, offering solutions such as customized prosthetics, implants, and even bioprinting tissues and organs. This technology enables the production of patient-specific implants and prosthetics, tailored to match the unique anatomy of each individual.

Additionally, surgeons use 3D-printed models for preoperative planning and simulation, enhancing precision and outcomes in complex procedures.

Food

The food industry has started exploring 3D printing for creating intricate and innovative culinary creations. From custom chocolates to elaborate cake decorations, 3D food printing offers chefs and food designers the ability to push the boundaries of culinary art.

While still in the experimental phase, 3D food printing has the potential to revolutionize aspects of food production and presentation.

Education

3D printing has become an invaluable educational tool, fostering creativity and innovation among students. Schools and universities use 3D printing to teach concepts in science, technology, engineering, art, and mathematics (STEAM), providing hands-on learning experiences that bring theoretical concepts to life.

This technology enables students to design and fabricate their projects, enriching the learning process and inspiring the next generation of innovators.

Types of 3D Printing Technologies and Processes

Vat Photopolymerisation

Vat Photopolymerisation involves curing liquid photopolymer resin using a UV light source. Technologies like Stereolithography (SLA) and Digital Light Processing (DLP) fall under this category. These processes are known for producing high-resolution prints with smooth surfaces, making them ideal for detailed prototypes and intricate designs.

The primary application of Vat Photopolymerisation is in industries that require precision and fine details, such as jewelry, dental models, and custom prosthetic manufacturing.

Material Jetting

Material Jetting deposits droplets of material layer by layer to build an object. This technology is known for its high accuracy and ability to use multiple materials within a single print, enabling the creation of full-color and multi-material objects.

Applications include producing high-detail prototypes, printing temporary items like casting patterns, and creating medical models with various textures and colors for surgical planning.

Binder Jetting

Binder Jetting uses a binder to bond layers of powder material. This process allows for the creation of complex geometries and large parts without the need for support structures. Binder Jetting is often employed for creating metal, ceramic, or full-color sandstone models.

The primary benefits of Binder Jetting include cost-effective large-scale production and the ability to produce parts with a wide range of materials, including metals and composites.

Material Extrusion

Material Extrusion, commonly known as Fused Deposition Modeling (FDM), is one of the most widely adopted 3D printing technologies. It involves extruding thermoplastic filament through a heated nozzle to build layers sequentially. FDM is popular due to its cost-effectiveness and ease of use, making it suitable for both professional and personal use.

Applications range from producing prototypes and functional parts to DIY projects and educational models. FDM is favored for its versatility and the wide range of materials available.

Powder Bed Fusion

Powder Bed Fusion processes, including Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS), use a laser to sinter or melt powder particles to form solid layers. These processes are known for their ability to produce high-strength, durable parts suitable for end-use applications.

Industries such as aerospace, automotive, and medical rely on Powder Bed Fusion for producing highly complex, functional parts with excellent mechanical properties and precision.

Directed Energy Deposition

Directed Energy Deposition (DED) involves melting material as it is deposited using focused thermal energy, such as a laser or electron beam. This process is particularly effective for repairing existing components or adding material to pre-formed parts.

DED is commonly used in the aerospace and defense industries for repairing and fabricating large parts that would be challenging to produce with other methods. This technology is advantageous for on-demand manufacturing and extending the lifecycle of expensive components.

Materials

The materials used in 3D printing range from polymers and metals to ceramics and composites, each with unique properties and applications. Thermoplastics like PLA, ABS, and PETG are popular for their ease of use and cost-effectiveness, making them suitable for general-purpose printing.

Advanced materials, including nylon, polycarbonate, and carbon fiber composites, offer enhanced mechanical properties, such as higher strength, impact resistance, and heat tolerance. These materials are utilized in demanding industrial applications and specialized projects.

Metal powders, including titanium, aluminum, and stainless steel, enable the production of high-strength parts for aerospace, automotive, and medical industries. Ceramics and composites provide additional options for areas requiring specific properties like heat resistance or electrical insulation.

Services

Navigating the world of 3D printing can be challenging for businesses and individuals without the necessary expertise or equipment. Fortunately, numerous 3D printing services are available to bridge this gap, offering professional solutions for prototyping, manufacturing, and customization.

These services range from on-demand part printing and design consulting to full-scale production and post-processing. Companies like Shapeways, Sculpteo, and Protolabs provide access to advanced 3D printing technologies, materials, and expertise, ensuring high-quality results.

By leveraging these services, businesses can focus on innovation and growth without the need for extensive in-house 3D printing infrastructure, making it easier to capitalize on the advantages of additive manufacturing.

Next Steps

| Section | Details |

|---|---|

| How Does 3D Printing Work? | Explains the use of 3D software and the slicing process needed to prepare models for printing. |

| 3D Printing Industry | Highlights the growth and market value of the 3D printing industry. |

| Examples of 3D Printing | Provides specific examples within sectors like automotive, aviation, healthcare, and more. |

| Types of 3D Printing Technologies and Processes | Outlines various 3D printing technologies, including Vat Photopolymerisation, Material Jetting, and others. |

| Materials | Details different materials used in 3D printing, highlighting their unique properties and applications. |

| Services | Discusses available 3D printing services for businesses and individuals lacking in-house resources. |